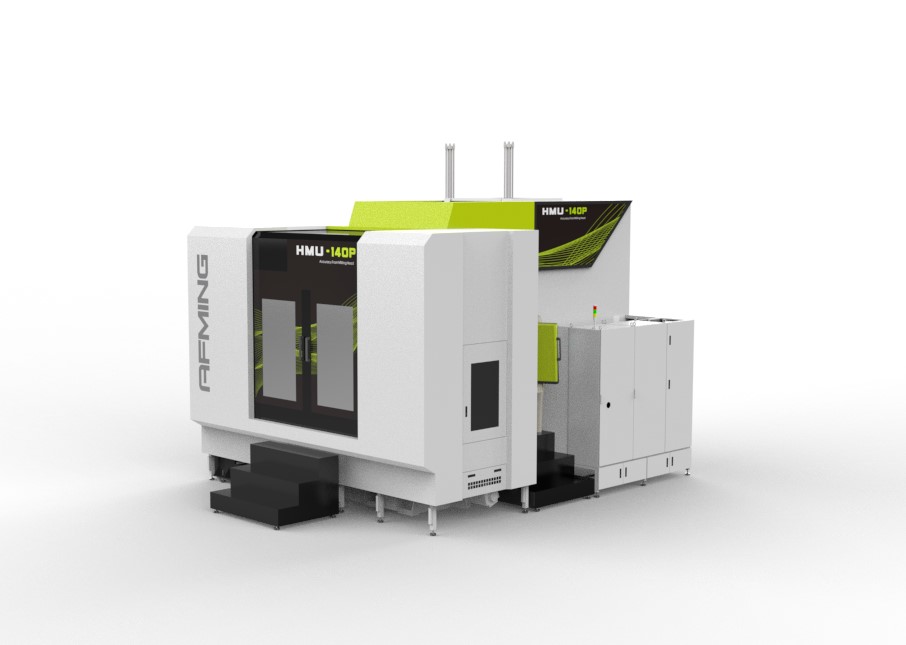

Les gens pourraient demander ce que sont les machines CNC ?

Les machines CNC, abréviation de machines à commande numérique par ordinateur, sont des outils de fabrication avancés qui utilisent des systèmes informatisés pour opérer de manière autonome des processus d'usinage de précision. Ces machines sont largement utilisées dans diverses industries en raison de leur efficacité, de leur précision et de leur polyvalence.

À quoi servent les machines CNC ?

Les machines CNC sont principalement utilisées pour des tâches nécessitant une grande précision et une répétabilité, telles que la découpe, le fraisage, le perçage et l'impression 3D. Des industries comme l'aérospatiale, l'automobile, la santé et l'électronique dépendent fortement des machines CNC pour fabriquer des composants complexes avec des tolérances serrées.

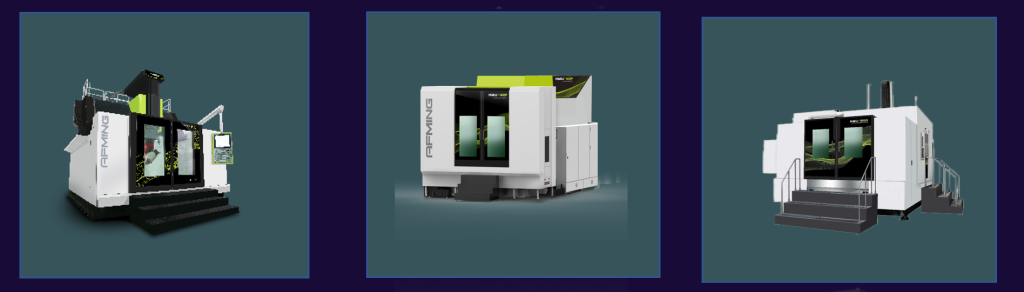

5 types courants de machines CNC

- Machine de fraisage CNC: Utilisée pour les opérations de découpe et de perçage.

- Tour CNC: Idéal pour façonner des pièces cylindriques.

- Fraiseuse CNC: Employée pour découper et façonner des matériaux comme le bois, le plastique et le métal.

- Découpeuse plasma CNC: Spécialisée dans la découpe de tôles métalliques à l'aide d'un chalumeau plasma.

- Imprimante 3D CNC: Permet la fabrication additive en superposant des matériaux pour créer des objets 3D.

Comment fonctionne une machine CNC ?

Les machines CNC suivent un ensemble d'instructions programmées pour contrôler avec précision le mouvement de l'outil de coupe ou de la pièce. La machine interprète les instructions et les exécute avec une grande précision, ce qui conduit à des processus de fabrication efficaces.

Connecter une machine CNC à votre ordinateur

Pour connecter une machine CNC à votre ordinateur, vous utilisez généralement un logiciel spécialisé ou une unité de contrôle qui communique avec le système de contrôle de la machine via un câble ou une connexion réseau. Cela vous permet de transférer des fichiers de conception et des instructions pour que la machine CNC les exécute.

Gagner de l'argent avec une petite machine CNC

Les petites machines CNC offrent des opportunités aux entrepreneurs et aux amateurs de générer des revenus grâce à des services tels que la fabrication de pièces sur mesure, le prototypage et la production artisanale. En proposant vos services d'usinage CNC à des entreprises locales ou sur des places de marché en ligne, vous pouvez monétiser efficacement votre machine.

Avez-vous besoin d'un ordinateur pour faire fonctionner une machine CNC ?

Bien que la plupart des machines CNC nécessitent une forme de contrôle informatique pour la programmation et le fonctionnement, des contrôleurs CNC autonomes sont également disponibles. Ces unités dédiées éliminent le besoin d'un ordinateur séparé et sont conçues spécifiquement pour exécuter des opérations CNC.

Courbe d'apprentissage des machines CNC

Apprendre à utiliser les machines CNC peut être difficile au début, car cela implique de comprendre les langages de programmation, la création de trajectoires d'outils et le fonctionnement de la machine. Cependant, avec de la pratique et de la formation, les individus peuvent rapidement devenir compétents dans l'utilisation des machines CNC pour produire des pièces de haute qualité efficacement.

En conclusion, les machines CNC sont des outils sophistiqués qui offrent d'immenses capacités aux fabricants et aux passionnés. En maîtrisant les fondamentaux de la technologie CNC et en explorant ses diverses applications, vous pouvez exploiter ces machines pour donner vie à vos visions créatives et entrepreneuriales.