What is a Ball Screw in a CNC Machine? – The Key to Precision Machining

A ball screw, a critical component in CNC (Computer Numerical Control) machines, plays a vital role in achieving high precision and accuracy in machining operations. This article will delve into the significance of ball screws in CNC machines and why they are considered essential for producing intricate and complex parts with tight tolerances.

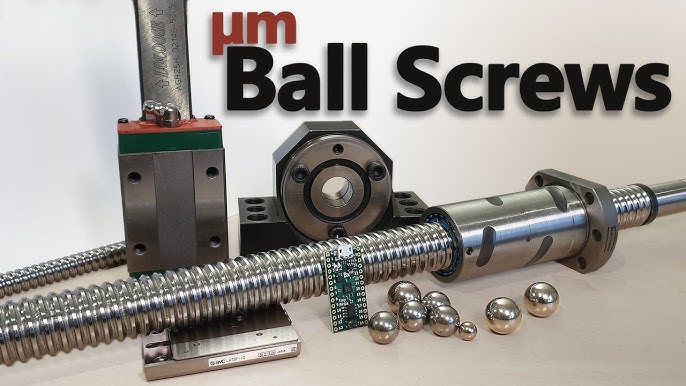

Understanding Ball Screws

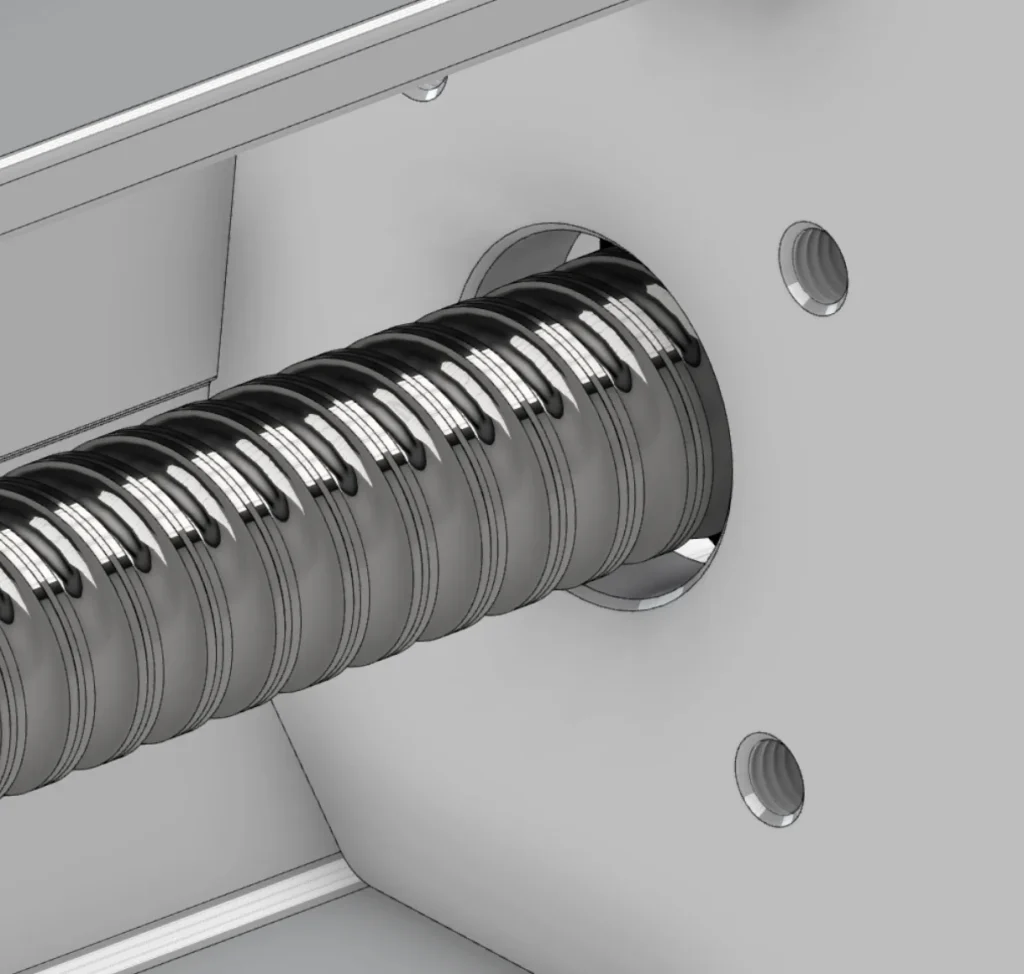

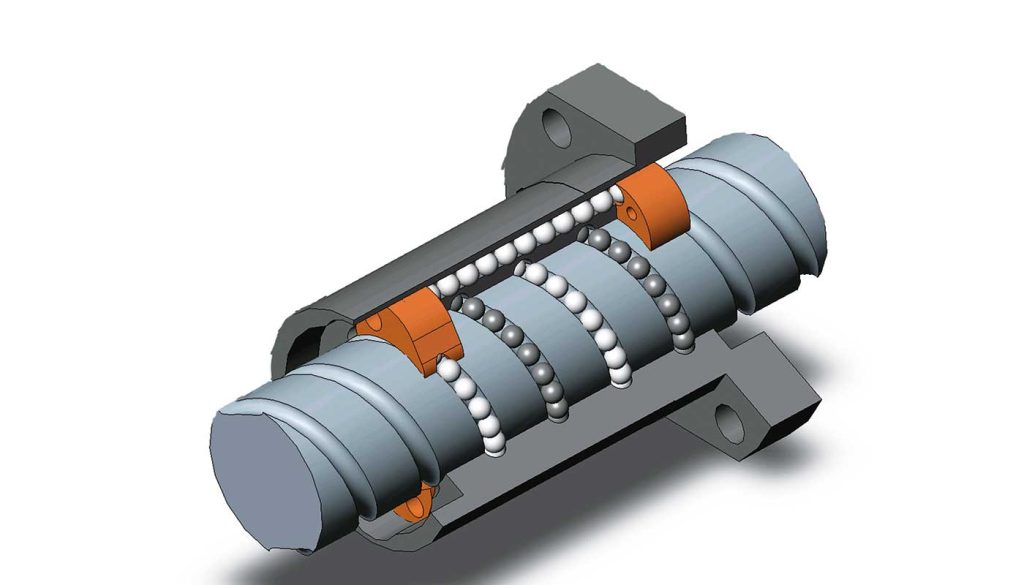

A ball screw is a mechanical linear actuator that translates rotational motion into linear motion with minimal friction. It consists of a screw (also known as a shaft) and a nut that contains recirculating ball bearings. The precisely designed helical groove on the shaft enables the ball bearings to circulate smoothly, converting rotational motion into linear motion with high efficiency. This design allows for smoother and more precise movement compared to traditional lead screws.

Importance in CNC Machines

In CNC machines, the movement of cutting tools or workpieces along multiple axes needs to be highly precise and repeatable. This is where ball screws shine, as they provide superior accuracy, reduced backlash, and improved efficiency compared to other linear motion systems. The low friction design of ball screws not only ensures smooth movement but also minimizes energy consumption, making them ideal for high-speed and high-precision machining operations.

Benefits of Ball Screws in CNC Machines

- Precision: Ball screws excel in providing precise linear motion, making them indispensable for intricate and detailed machining processes.

- Efficiency: The efficient transfer of motion in ball screws reduces power consumption, contributing to the overall energy efficiency of CNC machines.

- Low Backlash: Unlike traditional lead screws, ball screws have minimal backlash, ensuring that there is no play in the system and maintaining accuracy during machining.

- High Load Capacity: Ball screws are capable of handling heavy loads while maintaining smooth and precise motion, making them suitable for a wide range of machining applications.

Choosing the Best Ball Screw CNC Machine

When selecting a CNC machine with ball screws, several factors need to be considered to ensure optimal performance and reliability. Look for machines that use high-quality ball screws with precision-ground components to guarantee accuracy and longevity. Additionally, consider the speed and cutting forces involved in your machining operations to determine the appropriate ball screw specifications for your needs.

In conclusion, a ball screw is a crucial component in CNC machines that enables precise and efficient linear motion essential for achieving high-quality machined parts. By understanding the importance of ball screws and their benefits in CNC machining, manufacturers and operators can make informed decisions when selecting the best ball screw CNC machine for their specific requirements.

Why are ball screws so expensive?

Ball screws are more expensive compared to other drive systems like rack and pinion due to their precision and durability. A typical ball screw can last up to 15 years, while other systems may wear out much sooner[1].

What size ball screw for CNC?

When choosing the size of a ball screw for CNC applications, it’s essential to consider factors like pitch and diameter. For example, it has been found that ball screws larger than 12mm in diameter may require more torque from the motor, potentially decreasing machine performance[2].

What is the difference between ballscrew and Leadscrew?

The main difference between a ballscrew and leadscrew is the mechanism by which they transfer motion. A ballscrew uses ball bearings to reduce friction and provide more precise movement, while a leadscrew typically relies on sliding contact between the screw and nut, which results in less efficiency and accuracy[1].

How do I choose a ball screw for CNC?

When selecting a ball screw for CNC machines, factors to consider include the application requirements, such as load capacity, speed, precision, and environmental conditions. It is crucial to choose a ball screw that meets these specific requirements for optimal performance[1].

What are the reasons to use a ball screw?

There are several reasons to use a ball screw in CNC machines, including higher precision, lower friction leading to better efficiency, longer lifespan compared to other systems like rack and pinion, and overall improved performance in terms of speed and accuracy[1].