During CNC roughing, dynamic milling techniques are often used to improve machining efficiency. But is there a way to enhance efficiency in the more time-consuming CNC finishing processes?

The purpose of finishing is to ensure the final dimensional accuracy and surface quality of the workpiece. The surface quality achieved in finishing depends significantly on the scallop height left after machining.

What is Scallop Height?

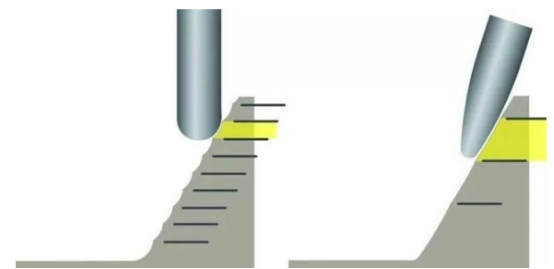

Scallop height refers to the maximum height of the residual material ridge left on the workpiece surface between two adjacent toolpaths after machining.

How to Reduce Scallop Height in CNC Finishing?

One feasible method is to decrease the stepover (the distance between adjacent toolpaths). However, this increases the number and density of toolpaths per unit area, extending finishing time.

Another feasible method is to use a larger-diameter tool. This is because a larger tool radius results in a larger radius of curvature at the point of contact with the material. For the same stepover density, this yields a smaller scallop height. Using a large-radius tool can reduce scallop height and achieve better surface quality. However, many workpiece features requiring finishing have narrow clearances that preclude the use of large-radius tools.

Characteristic Finishing with Large-Radius Tool Finishing with Small-Radius Tool

| Characteristic | Finishing with Large-Radius Tool | Finishing with Small-Radius Tool |

|---|---|---|

| Advantages | Smaller scallop height; Shorter cycle time | Simplified programming; Capable of machining fine features/narrow clearances |

| Disadvantages | Unable to machine fine features/narrow clearances; Higher risk of collision, complex programming | Requires reduced stepover/increased toolpath density for improved surface quality; Lo nger machining time |

How to Improve Surface Quality While Also Reducing CNC Finishing Time?

The scallop height is actually related to the radius of curvature at the contact point between the tool and the material, not directly to the tool radius itself. If we can increase the effective radius of curvature of the cutting portion of the tool while maintaining the overall tool body radius, it might be possible to simultaneously achieve improved surface quality and reduced finishing time.

By modifying the tool shape to increase the radius of curvature at the contact point during machining, the scallop height left by finishing is reduced. This allows for a significant decrease in the required number and density of toolpaths within the finishing area, thereby substantially reducing machining time and improving production efficiency.

A New Approach to Finishing: SuperChord Finishing Technology

Large-radius bull nose tools are a new category of milling cutters. Using these tools enables achieving the same surface quality with a larger stepover. Toolpath programming is key to effectively utilizing large-radius tools. Among the solutions, SuperChord Finishing Technology is a programming strategy specifically designed for efficient finishing with bull nose tools.

1. 3+2-Axis Machining Application Case

For SuperChord finishing in a 3+2-axis positioning environment, using contour (Z-level) and parallel strategies is still recommended. Unlike pure 3-axis machining, in 3+2 positioning, it’s crucial to select the appropriate tool plane (work plane). This ensures the tool’s radius maintains a stable tangency point contact with the material throughout the toolpath.

2. 5-Axis Simultaneous Machining Finishing Case

When performing SuperChord finishing via 5-axis simultaneous machining, the key point is controlling the tool axis orientation. This control ensures the tool contacts the material with a stable and optimal tangency point using its radius. The use of parallel and spiral (morphing/flowline) machining strategies is recommended.