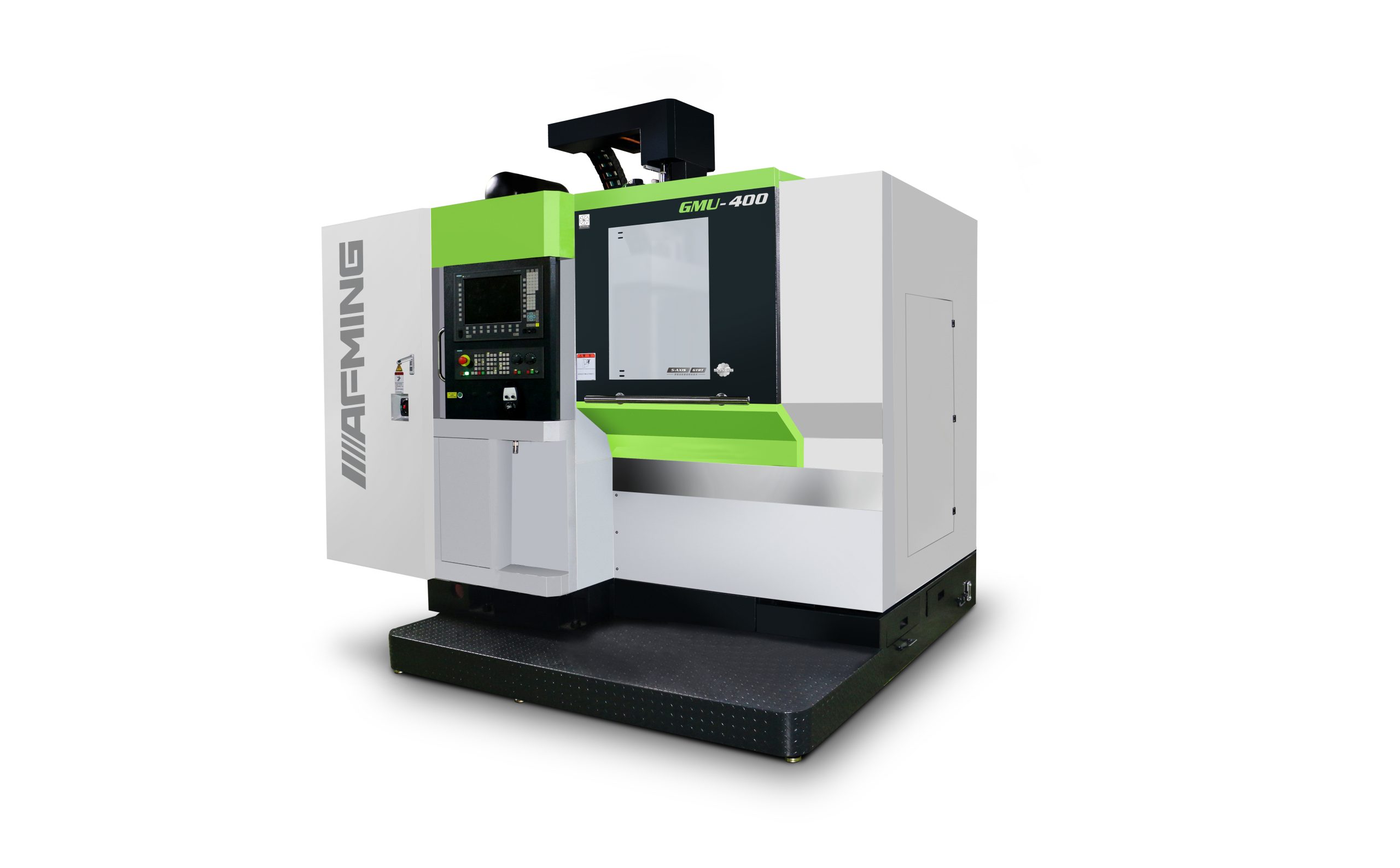

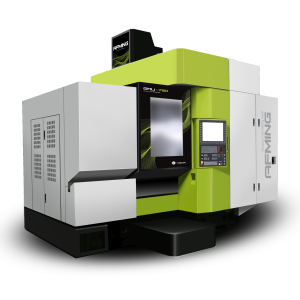

How About our Five-axis CNC Machine GMU-400?

The GMU400 five axis cnc machine adopts a high-rigidity fixed-beam gantry structure, which achieves machining performance and contour accuracy under high-dynamic conditions with high precision, high performance, and high efficiency. More importantly, GMU400 five axis machine center also equips the GTRT drive cradle technology, presenting high torque outputs of 1056 Nm on the A-axis and 430 Nm on the C-axis. From various difficult to cut materials to mold manufacturing with high surface quality requirements and even product contour accuracy, the GMU400 cnc machine is capable of handling them.

Five-axis CNC Machine GMU-400 Advantages

1, BAS Part Accuracy Testing

| NSA parts | Roundness accuracy | 0.012mm (X/Y feeding 3.000mm/ min and radius 100mm) |

| Roundness | <0.006mm(tapered 5-axis simultaneously moving) | |

| Flatness | <0.01 mm (φ80/300x400mm) Ra1.6~0.8 (φ80/300x400mm) |

|

| Surface roughness | ||

| +Certain discrepancies may exist between the data and those as set forth in the product catalog depending on the measuring environmental and processing C9 conditions,etc. | ||

| GMU-400 | ||

| X/Y/Z positioning accuracy/Repeated positioning accuracy | 0.006/0.003 mm | |

| A/C | 6/4 ARCSEC | |

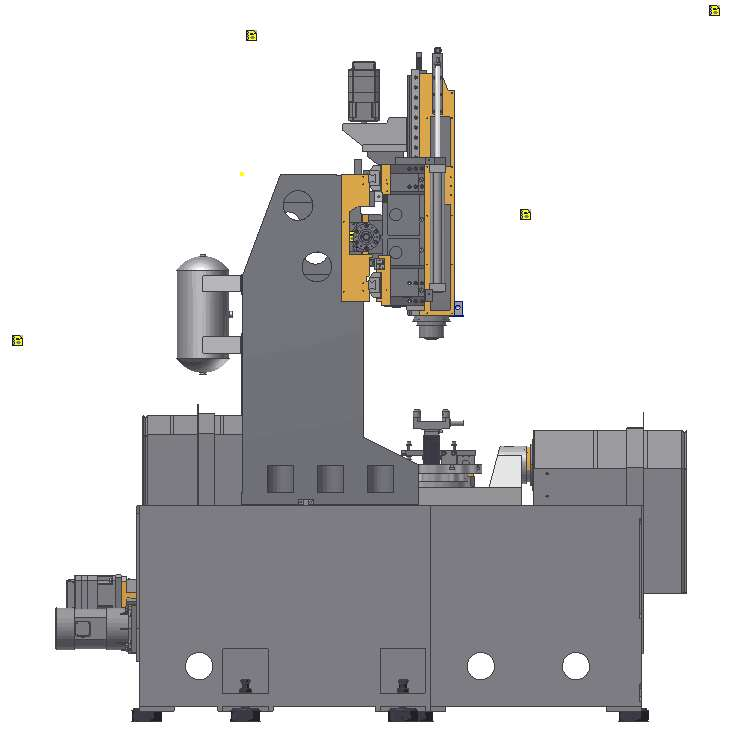

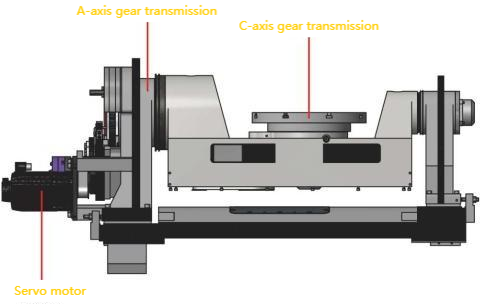

2, GTRT Gear Transmission Rotary Table Technology

The GMU-400 five axis cnc machine center has adopted the GTRT gear transmission rotary table technology for the first time in its class. Compared to the conventional rotary table drive ones, it can present greater torque output, higher rigidity, higher stability and better rotation precision.

European high-end gear transmission design concept

- AFMING gear anti-backlash patented technology

- A/C rotary table supported by two arms for high rigidity, strong load bearing, and high accuracy

- DIN5 grade imported ground gear technology

- Applicable to the processing of a wide range of materials, including steel, titanium alloy, and other high-hardness and high-tenacity materials

- A/C axis standard equipped with 0.5μm circular grating

- Easier chip removal and cleaning

- Having advantages of high torque, high accuracy, low energy consumption and long service life compared to DDR, worm wheel, worm, and roller cam drive modes

Travel (A/C): ±120°/360°

Maximum RPM (A/C): 20/30rpm

Maximum torque (A/C): 1056 /432

N.m Accuracy (A/C): 8″/4″

Bearing capacity: 120kg

| X/Y/Z-axis travel | 450/500/350 |

| Table size | φ400mm |

| Load bearing | 120kg |

| A-axis swing amplitude | ±120° |

| C-axis rotation | 360° |

| AC-axis torque | 1056/432 N.m |

| AC-axis rotation | 20/30rpm/min |

| A/C positioning accuracy/repeated positioning accuracy | 6/4 ARCSEC |

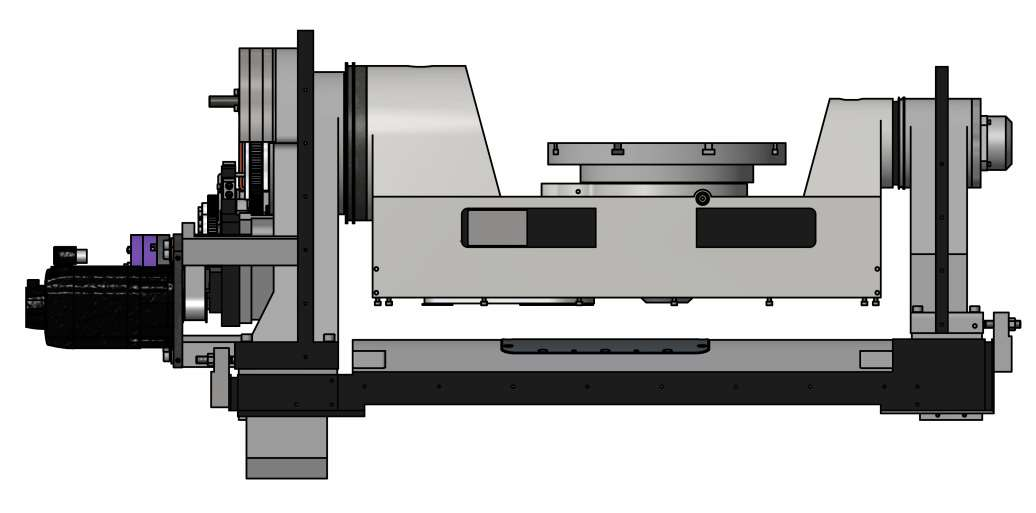

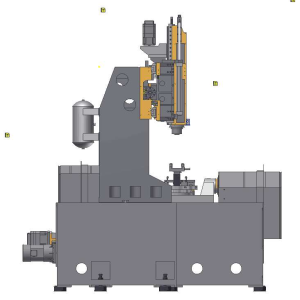

3, High Rigidity Fixed-beam Gantry Bed Structure

A fully-optimized fixed-beam gantry bed structure with all major components set up with a large number of bars and stiffeners combined with a thermally symmetrically balanced machine structure to guarantee the good rigidity, high torsional strength, thermal stability, and high guide rail accuracy of the five axie cnc machine tool.

4, Finite element analysis combined with dynamics optimization

Finite element analysis of bed components to ensure the ultimate performance and consistency of optimized structural rigidity and torsional rigidity.

Accurate calculation of the optimum dynamic rigidity under the actual working conditions to ensure the good cutting performance of bed structure and enable the bed to maintain toughness, rigidity, high accuracy, and vibration suppression even under heavy cutting conditions.

Precise calculation of the minimum cross compliance between the tool nose and the workpiece under actual working conditions to improve the chatter limit of high-speed milling of the five axis cnc machine tool and realize high- speed and high-accuracy machining efficiency.

Improved inherent frequency of the mechanical feed system and improved cut-off frequency of the electromechanical drive system to improve the value of position loop gain KV, shorten the positioning time, and reduce the lag of the feed system, thereby realizing high-response dynamic performance and high-speed and high- accuracy machining performance.

Highlights

- Moving parts optimized in terms of weight to achieve perfect dynamic performance.

- Z-axis optimized in terms of mechanics and dynamics to gain 30% more rigidity and dynamics than similar models.

- Extra-large area of vertical column base to provide stronger rigidity and stability.

- Finite element analysis, calculation and optimization of whole-machine structure and moving parts to achieve high milling efficiency, high machining performance, and extreme accuracy.

- First-order natural frequency of the whole machine up to 67HZ, which has greatly improved the anti-seismic performance and the static and dynamic rigidity of the machine tools.

- Three-axis acceleration up to 1.2G.

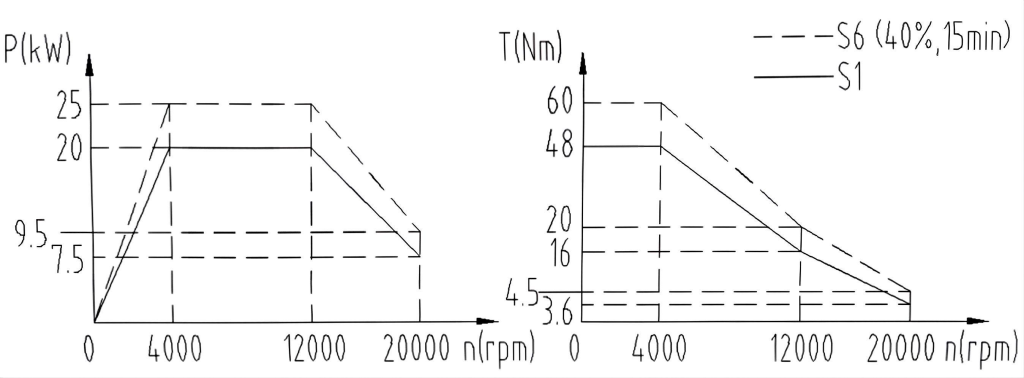

5, 20000 rpm Electric Spindle

| Power (S1/S6-40%) | 20/25 kW |

| Output torque (S1/S6-40%) | 48/60 N.m |

GMU400 Application

Application fields: + Automobile industry + Mold industry + Medical device + Optical lens

GMU400 five-axis CNC Machine Technical Specification

| Name | Unit | GMU-400 |

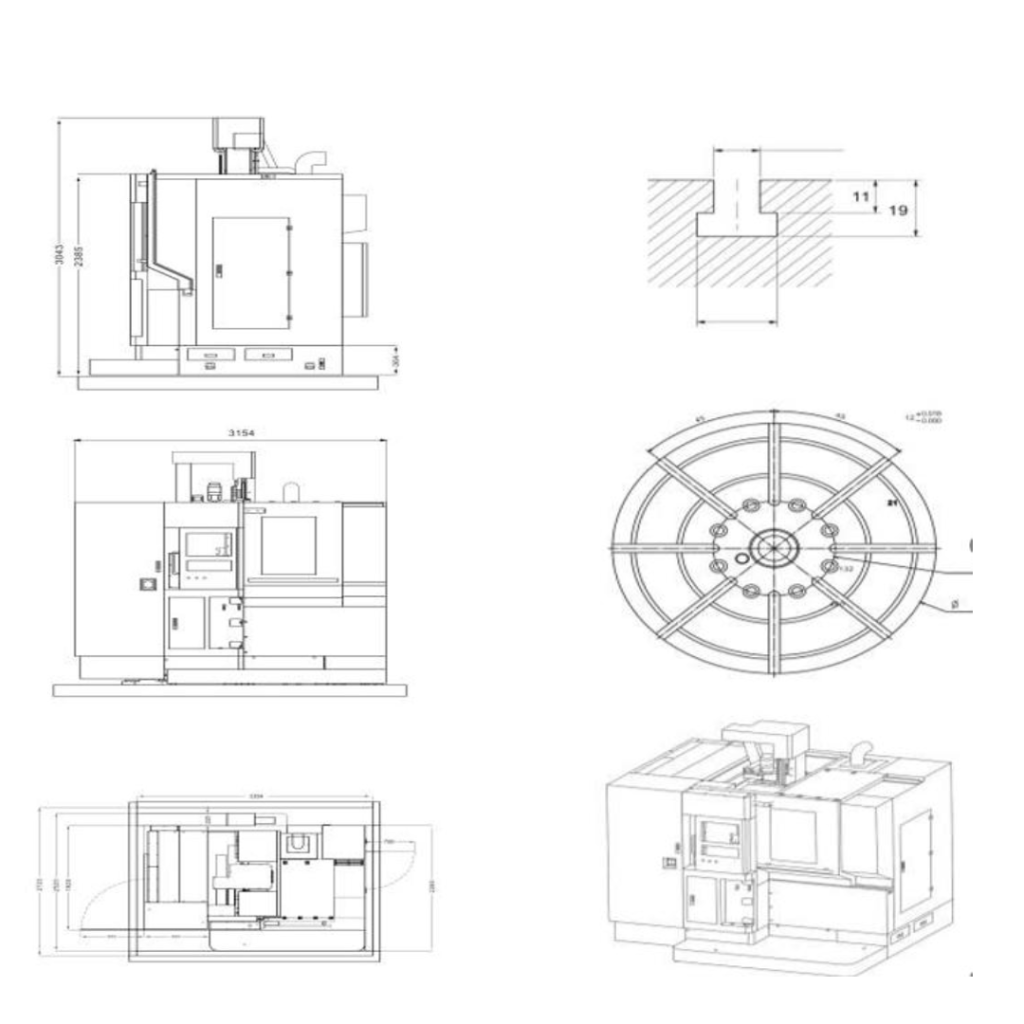

| XY/Z axis travel | mm | 450/500/350 |

| A/C axis travel | Degree | ±120/360 |

| Distance from spindle nose to worktable (when A-axis is at the position of 0 degree) | mm | 106-456 |

| Worktable size | mm | φ400 |

| Max load | kg | 120 |

| Spindle | ||

| Max spindle speed/taper | rpm | 20000/HSK-A63 |

| Spindle power (S1/S6-40%) | KW | 20/25 |

| Output torque(S1/S6-40%) | N.m | 48/60 |

| Feed system | ||

| XY/Z axis rapid feed speed | m/min | 36/36/20 |

| Max cutting feedrate | m/min | 10 |

| A/C axis rapid feed speed | RPM/min | 20/30 |

| Positioning accuracy/repeated positioning accuracy (ISO 10791-4:1998) | ||

| XYIZ axis positioning accuracy | mm | 0.006/0.006/0.006 |

| XYIZ axis repeated positioning accuracy | mm | 0.003/0.003/0.003 |

| A/C axis positioning accuracy/repeated positioning accuracy | ARCSEC | 6/4 |

| ATC | ||

| Tool number | pcs | 30T |

| Tool change time(tool-tool) | sec | 2.5 |

| Max tool length | mm | 230 |

| Max tool diameter (no adjacent tool) | mm | φ75/φ120 |

| Max tool weight | kg | 8 |

| Machine size | ||

| Height | mm | 3100 |

| Floor area (length*width) | mm² | 3740*3300 |

| Net weight | kg | 8000 |

| Power | kw | 40 |

Standard configuration

| No. | Standard configuration | |

| 1 | System | Heidenhain iTNC 620 |

| 2 | sheet metal | Capping full enclosure body sheet metal (including water tank) |

| 3 | Spindle | HSK-A63-20000rpm AFMING electric spindle |

| 4 | A/C Cradle turntable | Gear rotation structure (imported DIN5 grade grinding gear) |

| 5 | Spindle cooler | Water cooler (China) |

| 6 | Tool setting instrument | Marposs contact |

| 7 | 3axis linear grating | HEIDENHAIN |

| 8 | AC axis circular grating | HEIDENHAIN |

| 9 | Tool magazine | HSK-A63-48T flat tool magazine |

| 10 | Chip removal system | Spiral chip conveyor |

| 11 | guide | X-axis 35 roller guide,Y-axis 45 roller guide,z-axis 35 Guide |

| 12 | Screw rod | X axis r40x20,Y axis r50x20,Z axis r40x20 |

| 13 | Z-axis balance system | Air pressure balance system (Japan SMC) |

| 14 | Electric box thermostatic system | Constant temperature of air conditioner (Tongfei) |

| 15 | Pneumatic system | Japan SMC |

| 16 | Hydraulic station | Taiwan 7OCEAN |

| 17 | Automatic lubrication device | Grease type (Liubian,China) |

| 18 | Cleaning of processing area | Air gun and water gun for cleaning |

| 19 | Work light | LED light |

| 20 | Warning light | Three color warning light |

| 21 | Tool box and anchorscrew | Tool box and anchor screw |

| 22 | Five axis center correction package |

(including 3D probe)Heidenhain |

| 23 | Automatic ceiling components |

GMU600-Automatic ceiling components |

| 24 | Oil mist collector | GMU600-QS-750 (Qiushan Machinery) |

| 25 | Safety door lock | |

Options configuration

| ltems | Specification |

| System | Heidenhain iTNC 640 |

| Worktable size | 630mm |

| HSKA63-60T tool magazine | GMU600-230000 |

| Hexagon laser tool setter | GMU600-180001 |

| Blum laser tool setter | GMU600-180000 |

| CTS 30bar spindle center water outlet | |

| CTS 50bar spindle center water outlet | |

| CTS 70bar spindle center water outlet | |

| Automatic door | |

| Workbench oil pressure tooling port pipeline components(4 oil lines,1 airtight) | Pipeline components of worktable oil pressure tooling port |

| Zero point positioning component of the turntable(3-way oil,2-way gas with airtightness) | Zero point positioning component of turntable |

| Paper tape filtering component | Paper tape filtering component |

| Post processing services | UG NX Post processing(Heidenhain System) |

| Post processing services | Hmp Post processing(Heidenhain System) |

| Post processing services | Powermill Post processing(Heidenhain System) |

| Post processing services | Mastercam Post processing(Heidenhain System) |

| Post processing services | On machine measurement and compensation module |

| Post processing services | The Heidenhain system of NX software for online alignment and measurement |

| System Function Options | Five axis collision prevention |